Haitian Jupiter III Series (4,500 – 66,000 KN)

| Available from 4,500 to 66,000 kN |

| Short dry cycles |

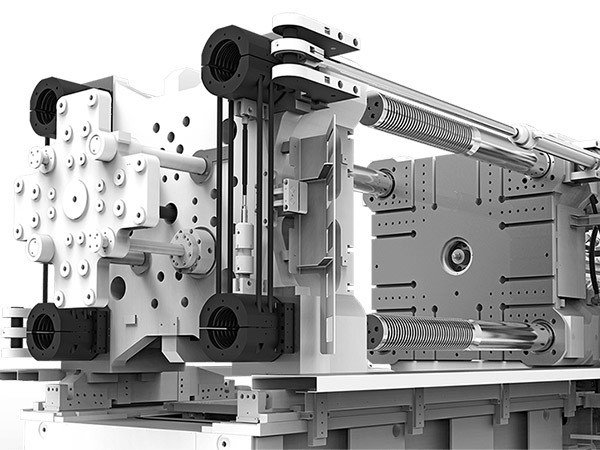

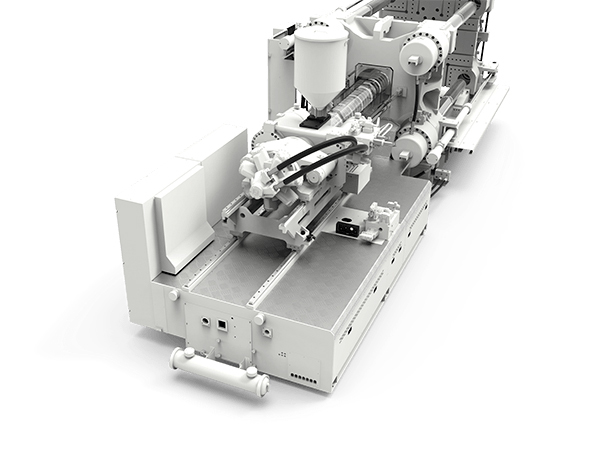

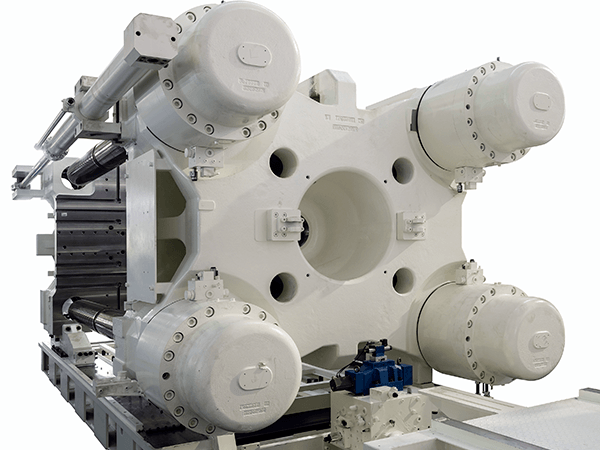

| Large MOLD space, compact machine design |

| Energy-efficient servo-technology |

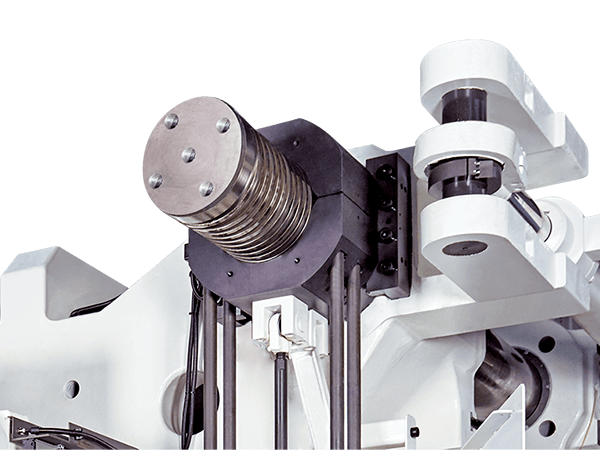

| Fast response time and high positioning accuracy (± 0,05 %) |

| KEBA control technology |

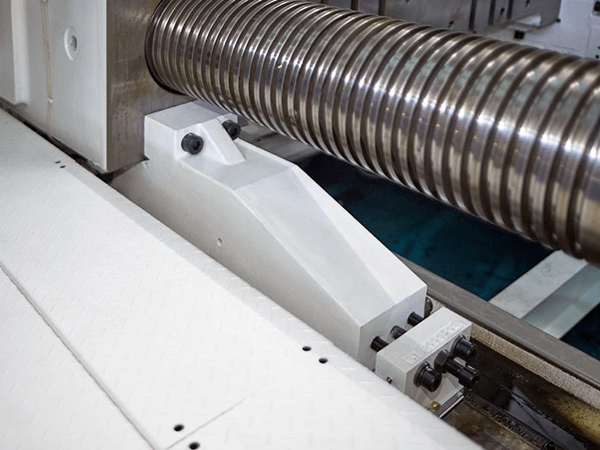

The Haitian JU III Series, as developed based on Haitian’s extensive experience in sustainable research and development of two-platen solutions in the past two decades, has significant improvements to the previous machine generation and provides more advantages for many different molding applications. The new design incorporates additional functions and user benefits which greatly enhance the machine performance and part quality. With flexible clamping unit to injection unit combinations, the machine can be tailored to specific or general molding applications.

As a product with Technology to the Point, the new generation of the Haitian Jupiter Series provides a wide variety of combination possibilities in a compact footprint, which maximizes the usable space of the plants to the customers’ benefit. No matter large parts such as trash bins and logistics boxes, or high-precision automotive parts and high-tech parts with high surface quality such as white goods, JU III Series injection moulding machines provides the best solution for customers.